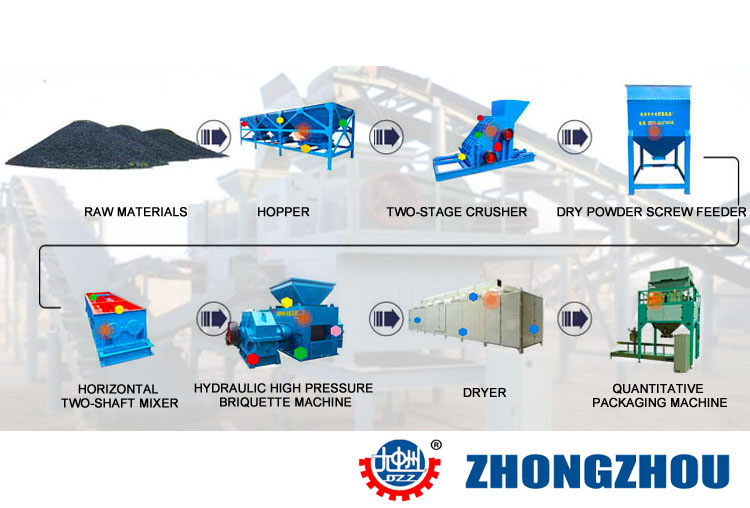

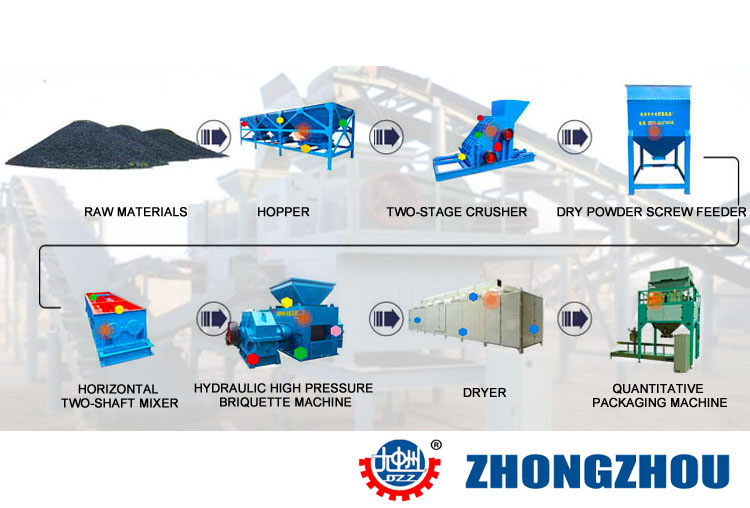

3-4 Ton per Hour coal briquettes production line

The coal briquette machine also be named coal briquetting machine, coal ball press, coal briquette press, it is a briquetting machine which press coal, coke, liginte, charcoal into briquettes with different shape such as round, oval, pillowed, egged and squared. The final coal briquettes widely used in home-cooking, burning for warming, industry furnace. For the small capacity, there are a proposal with 3-4T/H coal briquettes production:

1. Vertical Crusher ZZLP500

Vertial Crusher is designed and optimized in accordance with international latest crushing technology. It can crush all kinds of hard ores in mining, metallurgy, refractory, cement , coal, glass, ceramics, and electric power industries.

Widely used in stone crushing line and sand production line, Compound Crusher is suitable for limestone, clinker, coal and other minerals of building materials, mining, metallurgy, chemical industry. Its compressive strength is not more than 140 Mpa and humidity less than 15%.

For this 3-4T/h coal briquettes output production, ZZLP500 vertical crusher offer its technology data as follows:

Model: ZZLP-500

Power: 11kw

Capacity: 3~6t/h

Overall size: 1000x630x1350mm

Rotation speed of main shaft: 1150r/min

Max size of feeding: ≤200mm

size of discharging: ≤3mm

Weight:700kg

2. Horizontal Two-shafts Mixer ZZWJ500X2000

Double shaft mixer is used for mixing materials continuously and uniformly. During mixing, the raw material can be uniformly mixed with binder, and after mixed, the blended materials can be continuously sent to the conveyor. It is usually applied to mix coal, mineral powder, iron powder, coal slurry, sludge, clay, etc. Double shaft mixer has the features of high mixing speed and good uniformity.

Model: ZZWJ500x2000

Power: 7.5kw

Capacity: 1-10t/h

Speed of main shaft: 35r/min

Overall dimension: 3200 x1200x 520mm

Weight: 800kg

Mixing type: mixing blade or mixing vane

3. Coal Briquette Machine ZZXM-4

The coal briquette press machine is mainly used to press powder materials that are hard to be shaped. The coal briquetting machine has the features of strong pressing pressure, adjustable revolution and screw conveying device. This coal briquette machine can save energy and protect the environment and the final products are convenient to be transported, thus improving the utilization of the waste materials and have excellent economic and social benefits. In addition, the power consumption of this coal briquetting machine is low.

Zhongzhou coal briquetting machine is casted with 65 manganese steel, and with special heat treatment, its hardness can reach over 58°. The roller skin adopts composite assembly, so that it can be changed when abraded. Zhongzhou coal briquette machine or coal briquette press machine has a shock absorber which can better protect the equipment from the impact of hard materials. Fote coal briquetting machine is designed with ball bowl adjustable device to make sure the ball bowls of the two rollers are always in the adjustable range.

The requirement of raw materials for coal briquette machine:

1.The grain size of raw materials should less than 1mm which should be controlled between 30~40%, and the materials between 1mm and 2mm should be 30~40%. The maximum grain size that no large than 3mm should be about 20%.

2.The moisture of raw materials should be 8~12% after mixing with binder and water.

3.It is absolutely not allowed that the slab and other massive sundries with high hardness are included in the material or the roll and spindle will be damaged. The consumer construction should install the deferrization equipment in the production(briquette production).

Model: ZZXM-4

Power: 11kw

Capacity: 3-4t/h 10000t/year

Overall size: 1215x1150x1835mm

Weight: 2.1t

Roller width/diameter: 250mm/360mm

Total pressure: 15t

Rotary speed of main spindle: 18r/min

Line pressure of roll face: 0.5t

Pressure type: Wedge papilionaceous spring type

Roller materials: 65Mn

Heat treatment: 52~58°

Structural form: Four rollers double pressure

Briquette shape: round, pillow-shaped, oblate, oval-shaped, diamond

Briquette size:30~60mm

4. Belt Conveyor ZZPD500

For belt conveyor connect with every machine,its length depend on customer's real workshop.

5. Other Auxiliary equipment

In general, a compelet coal briquettes production line of 3-4ton per hour output, should set some auxiliary equipment such as binder feeder, silo hopper, electric cabinet, drying machine etc. These should be provided depend on customers' demands.

Henan Zhongzhou Heavy Industry Technology Co.,Ltd is a large-scale and professional manufacturer of briquette machinery, with three professional industrial workshops and more than 120 machine machining, welding and assembly equipment with large and medium size. Zhongzhou Machinery has won wide praise at home and abroad by the exquisite techniques and advanced technology, and it’s also become the large mining machinery export base in China. Welcome to inquiry us coal briquette machine, we will offer you a complete proposal depend on your raw material, demands and expectation

3-4 Ton per Hour coal briquettes production line: