Phosphogypsum is the industrial waste residue of phosphoric acid or phosphate fertilizer industry and some synthetic detergent industry, can be used as cement retarder, and at present the government promote energy conservation and emission reduction, waste residue utilization, conservation of resources, environmental protection and other policies. Now the cement plants use phosphogypsum gypsum instead of natural gypsum as the cement retarder.

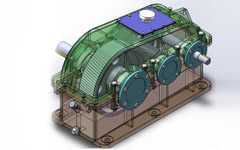

Zhongzhou phosphogypsum briquette machine will directly press phosphogypsum into 20-80mm round briquettes and without any adhesive, and the production rate above 95%, the hardness of briquettes pressed is very strong, should not be easily broken when handing and loading, and then supplied to the cement plant using retarder instead of natural gypsum, phosphogypsum briquettes product purity guaranteed, direct forming and into briquettes, high strength, suitable for all kinds of transportation, improve product transportation capacity; phosphogypsum briquette machine has the advantages of compact structure, convenient maintenance, simple operation, short process, low energy consumption, low failure rate, the main part rollers adpot materials 9Cr2 steel forging, greatly improved the wear resistance and pressure resistance, so the whole machine has a long service life.

Zhongzhou phosphogypsum briquette machine according to the customer's demands to provide the following process:

Project 1. phosphogypsum--- hopper silo--- press machine---briquette machine---final briquettes product

Project 2. phosphogypsum--- hopper silo--- rotary dryer----press machine---briquette machine---final briquettes product

Project 3. phosphogypsum--- hopper silo--- rotary dryer----press machine---briquette machine---vertical dryer---final briquettes product

Project 4. phosphogypsum--- hopper silo--- rotary dryer----press machine---briquette machine---turning dryer---final briquettes product

Phosphogypsum briquettes production supporting equipment are as follows:

1. Gypsum powder: it is the industrial waste residue of phosphoric acid or phosphate fertilizer industr, can be used as cement retarder.

2. Special gypsum feeder: control of the whole production line, solve with gypsum wall not falling, not continuous and uniform feeding, ensure special equipment for drying machine feeding uniform.

3. Rotary dryer: the water is higher than 12% of the phosphogypsum be dried to below 8%-10%, easy to pressing briquettes.

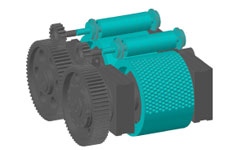

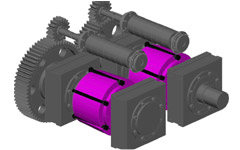

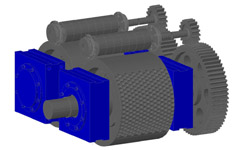

4. Press machine: press phosphogypsum more solid, increase the density of gypsum, a kind of auxiliary equipment. Press machine improve the briquetting rate of phosphogypsum, the characteristics is as following: It works for loose materials that not easy to be formed , Pre exhaust and compaction, make materials be briquetted easily, the machine assembling reasonable ,compact structure, stable operation, reliable performance.

5. Phosphogypsum briquette machine: press gypsum into briquettes without any binder, the production rate more than 95%.The final briquettes is more hard, can be keep the shape when loading and unloading in transportion. Product purity guaranteed.

6. Turning dryer: it is to drying gypsum briquettes below 3% water content. The gypsum briquettes is evenly placed in the net, through the hot air drying to complete drying task.

7. Vertical dryer: It also can be used for drying final briquettes, the gypsum briquettes was put into the top of dryer by belt conveyor, and in the process slow down, the hot air bring the water of briquettes, quickly be dried to 3% moisture, this machine has small area, easy operation and low maintenance cost.

Zhongzhou company based on phosphogypsum briquette press equipment technical services, to create maximum value for clients, The phosphogypsum briquette machine produced has the high pressure, high finished product rate, high strength, fully meet the requirements of the operation of lime production, cost reduction for lime production, optimized operation, create the conditions for the realization of maximum benefit, we sincerely welcome all enterprises to explore, mutual benefit and win-win.