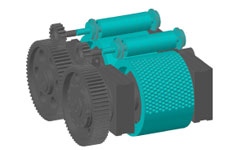

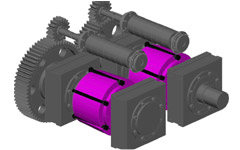

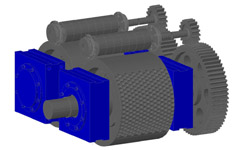

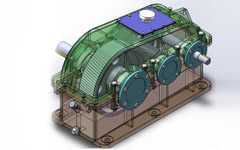

1.principle structure of turning plate dryer

Turning plate dryer is based on the principle of two-way conveyor drying equipment. The briquettes be pressed by high pressure briquette machine wich contain moisture, the briquettes be into hopper at the end of dryer and inflow the upper plate , hopper has cushioning and distribution effect for briquettes, the briquettes material run smoothly by plate to head of dryer, inflow the next plate by turning mechanism, and then back to the tail of dryer, like this running direction, the briquettes material will be dried gradually in hot air and sent out at dryer tail. Hot air source can be configured based on user condition, such as stove, hot gas , etc.

2.Advantages of turning plate dryer

1. Rail track is made by special process, to be designed depend on characteristics of the briquettes material properties and distribution, ensure its straightness and strength, and the chain runs a small resistance,the turning plate dryer with rail is our special design which ensure plate tipping freely.

2. Automatic chain tensioning device, chain plate running smooth, setting a good guide can effectively get rid of the chain off, deviation and so on.

3. The chain plate adopt resistant steel wich be punched into mesh plate, high strength , not easy to deformed, good air permeability. There are chain and wheel on both sides of plate, ensures that both sides of the wheel run reposefully ,easy disassembly.

4. Chain plate select electromagnetic speed or frequency control drive according to the conditions , and can be adjusted speed according to need , control the drying time .

5. With a fire precaution, The front, middle and tail part all are equipped with temperature measurement devices , digital display temperature which can be easy to control the internal temperature , flue inlet be set a gate , once the mechanical failure, cut off heat immediately to prevent fire.

6. According to material moisture and material properties, the use of up layer distributed hot air, hot air distribute evenly, to effectively prevent the material cracks due to sudden heat, reducing breakage rates.

7. According to the material moisture and air temperature ,reasonably chose negative or positive wind pressure, which is the outcome of our many years of practice .

8. The bottom of dryer set special cleaning device , it can clean out dust , avoid equipment failure .