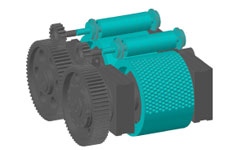

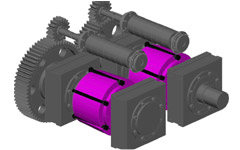

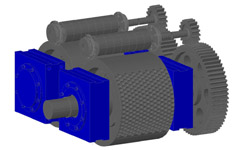

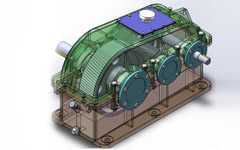

Zhongzhou dry powder briquette machine/drying powder briquette press/high pressure briquette machine is different from ordinary briquette machine, it is used to press the special materials which not allow any water and addtive in briquetting process such as: calcium aluminate, limestone, quicklime, cryolite, chemical fertilizer, magnesium powder, aluminium dust ,alumine etc. The final briquettes are widely used in refractories, metallurgy, chemical industry, power plants and other industries, the briquettes pressed by dry powder briquette machine is energy saving and environmental protection, convenient transportation, improve the utilization rate of waste, with advantages of continuous production, high automation, good economic and social benefits.

Cause of its high purchasing and operating cost, Zhongzhou suggest customer to choose the ordinary briquette machine instead of dry powder briquette machine if your raw materials allow to add addive and water.

The feeding size of dry powder brqiuette machine/drying powder briquette press/high pressure briquette machine should be controlled in 60-200 mesh, and the maximum size not more than 2mm which also not more than 20%, humidity of materials under 3%.

The final briquettes can be customized by user, offer us the requirement for shape/size of briquettes, we will design and manufacture the mould roller as your demands.

Characteristics and advantages of dry powder briquette machine production line

1, high automation, reduce the labor, simplify operation.

2, dry powder briquette machine is able to press the materials without any binder and water, the it have low cost to set a whole production line.

3, production capacity, can meet the production needs of large enterprises.

4, dry powder briquettes production machine line can achieve continuous operation, can meet the needs of uninterrupted operation.

5, dry powder briquette machine production line can be reliable, stable, simple and convenient equipment maintenance

Requirements for materials in dry powder briquettes machie production line:

1, material size is in 80-200 mesh.

2, don't contain metal lump material in process such as nails, or it is likely to damage the roller.

3, the feed must be sufficient, so briquette ratel will be guaranteed.

4, the material no need without water or adhesive.

Zhongzhou company based on dry powder briquette press machine technical services, to create maximum value for clients, dry powder briquette machine we produced has the high pressure, high finished product rate, high strength, fully meet the requirements of the operation of steelmaking and making briquetting, optimized operation, create the conditions for the realization of maximum benefit, we sincerely welcome all steel enterprises to explore, mutual benefit and win-win.