Our company designs and developments of vertical dryer series which owned national patents, and issued patent certification by the State Intellectual Property Office. Vertical dryer is particularly suitable for small and medium coal briquettes drying production line, it has the advantage of a small investment, good drying effect, small working area wear-free operation, maintenance-free operation. Its structure is: Fan, drying part, feeding, discharging part. In dryer, hot air go into briquettes gap through hot air pipe, hot air take away water of coal briquettes in the exchange process , coal briquettes from the top to down, slipping under the action of gravity, when they go into the end of dryer, the moisture content of coal briquette will is reach about 2%. This machine can also be used in coke briquettes, black non-ferrous ore briquettes dehydration. In the chemical industry, coal briquettes industry, metallurgical industry,this kind dryer has excellent effects and endurable working.

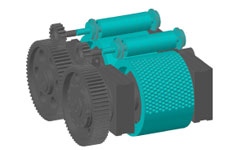

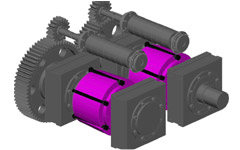

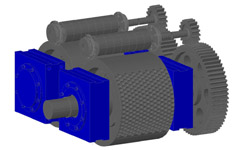

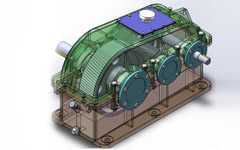

1.Overall Component of vertical dryer.

The component of vertical dryer: Drying part, The elevated work platform,Induced draft fan, motor of induced draft fan, oven, feeding conveyor, discharging conveyor(we offer design drawing of oven, foundation of equipment, guide client to building, civil work be operated by client).

2. The characteristics of vertical dryer

1, the economy characteristics:

Compared with other drying equipment, using vertical dryer which can reduce half of the investment, the land use area is their 1/5-1/3, greatly reducing energy consumption and operating costs, can save about five workforce.

2, the handling characteristics:

It is simple for operation and maintenance of this dryer,There are no mechanical transmission parts in hot air furnace ,no need maintenance usually,continuous working, high efficiency, large output.

3, the quality characteristics:

The a variety of materials briquettes be out from briquette machine, the moisture content of briquettes is about 8-12%, after drying, the moisture is reduced to 1.5-3%, fully meet the strength and storage requirements, reducing the breakage rate, guarantee its neat appearance.

4, the heat source types:

The heat source of dryer can be coal, coal gas,nature gas, exhaust gas, waste heat etc. simply adjust the stove to set up fire-jet head. Our company design it based on user’s conditions.

3.The basic working principle of vertical dryer

Drying principle for vertical dryer: wet briquettes made of various material is transported into the top of dryer by belt conveyor, then be distributed by distributing device to the roof on the dryer, due to its own weight of briquettes, which is moving slowly down ,hot air out of the hot air duct cross into gap of briquettes, The evaporation moisture was taken away by the strong hot air flow. Briquettes are fully dried in two hours after heat exchange and evaporation processes.

4.The main usage of vertical dryer

Vertical dryer is widely used in the coal industry, metallurgical industry, building material industry, etc.; mainly used for coal briquettes , coal bar briquettes,fluorite briquettes,metallurgical slag briquettes - dust, iron oxide, ore powder, vanadium, nickel laterite .....,vertical dryer more fully modular its unique role especially in large capacity coal briquettes production, processing and manufacturing enterprises.