Ferrosilicon briquette is composed of silicon, iron and a small amount of carbon and other elements of alloy, it is a widely usage. Ferrosilicon briquette is a common compound deoxidizing agent in steelmaking, but also the deoxidizer of iron metal in production of low carbon ferromanganese and electrosilicothermal method. Ferrosilicon briquette can take continuous operation in large, medium and small smelting furnace for smelting, using ferrosilicon briquettes can reduce the cost than the use of ferrosilicon alloy block.

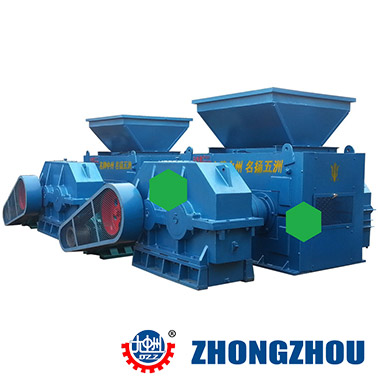

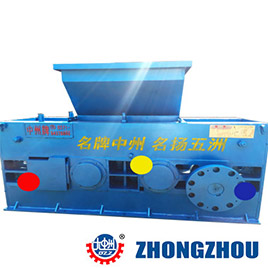

Zhongzhou hydraulic ferrosilicon briquette machine is designed forferrosilicon,silicomanganese,iron powder, iron oxide, oxide coating, iron scale, iron ore concentrates,iron mud to make briquettes, high pressure, stable operation, high productivity, high degree of automation, production efficiency, low failure rate, convenient maintenance, so Zhongzhou ferrosilicon briquette machine are welcomed by many domestic and foreign enterprises.

The flow chart of ferrosilicon briquettes production line:

Briquettes process generally include batching, grinding, mixing, pressing and drying.

1. Hopper silo, or box type quantitative feeder, it load and convey raw materials to crusher evenly.

2. Two-stage crusher, the raw material be crushed in to the appropriate size, generally it is most suitable that not more than 5mm.

3. Liquid mixer, be used for mixing liquid binder, if use powdered binder, it should use a drying powder feeding equipment.

4.Horizontal two shafts mixer, evenly mixing raw materials, adhesives andwater together, the adhesive will be evenly distributed in the raw materials so that achieve better strength, making briquettes better.

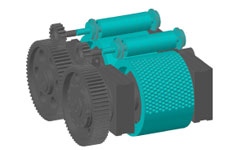

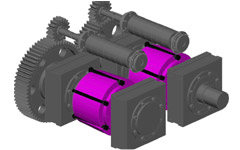

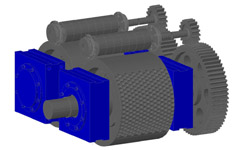

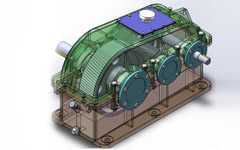

5. carbon silicon briquette machine is a core of whole production line, it press materials into briquettes, the briquettes' size and shape can be customized, zhongzhou can produce various shapes of rollers.

6, vertical dryer, drying the wet briquettes which came from briquette machine,the briquettes can be dried to 3% water content, finished briquettes will put in storage or packaged.

7, belt conveyor, connected to devices, it is guanrantee for the whole manganese ore briquettes production line to realizes full automation.

The requirements for raw materials of ferrosilicon briquettes production:

1, the particle size of the raw material should be between 0-5mm.

2, can not contain impurities, especially large metal. Such as nails, or iron, rocks, it very likely damage roller and spindle..

3, the feeding of whole produciton line should be stable, even, ensure workloads of briquette machine stable, to get high efficiency of production.

Zhongzhou company based on metallurgical briquette press equipment technical services, to create maximum value for clients, ferrosilicon briquette machine we produced has the high pressure, high finished product rate, high strength, fully meet the requirements of the operation of steelmaking, cost reduction for the production of smelting, optimized operation,shorten smelting practice term, speed up the rhythm of steel making, create the conditions for the realization of maximum benefit, we sincerely welcome all steel enterprises to explore, mutual benefit and win-win.