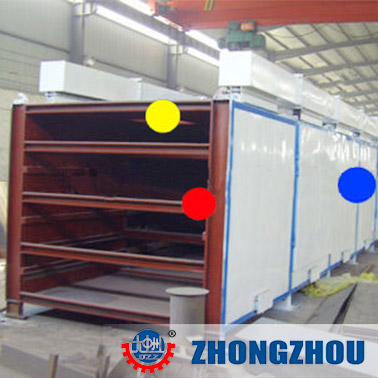

Mesh belt dryer is a drying equipment which utilize steel material mesh as a transmission belt, carrying materials for continuous drying, which can be continuous production, which production large capacity, is the most appropriate and suitable for producing more than 20 tons per hour briquettes assembly production line, due to the transfer belt is net, it is also used for drying various regular or irregular lumps. This machine work with briquette press machine, coal briquette extruder machine as a whole production line , it also can be used as drying equipment separately.

The function of Mesh Belt Dryer:

This machine is a flowing and continuous,large capacity drying equipment which work stably in briquettes production line . The machine is used for drying the piece, plate-shaped and particle materials, the conveyor directly transports finished briquettes to the pallet conveyor, and the scraping plate on the upper end of the pallet conveyor arranges these balls evenly on the dryer, through the briquette of air permeability with hot air exchange to remove he water, achieving drying effect, ensuring continuous production of briquette equipment or other material production line.

The material is slowly into drying by machine head though the drying chamber, linear speed of material depending on the moisture content and type of material. the speed motor can be adjustable linear speed. The linear speed 630-1800 / min which is arbitrary adjustable, material is discharged by the end of discharge after drying(dipole layer material is discharged though machine head, Odd layer material is discharged from machine tail), In the process of dryer running, as a result of the action of fan, hot air passes through the blast pipe import into dryer to drying material from the top to the bottom, then through the duct outlet discharging by the air outlet(heated-air circulation)

To get the best dry effect and appropriate capacity, The combination of Material, the water content, the linear speed of net belt, air volume and temperature must be appropriate and reasonable.

The main purpose of mesh belt dryer

Mesh belt dryer is widely used in the coal industry, metallurgical industry , building materials industry , chemical fertilizer industry, food industry , etc. ; mainly used for coal briquettes class , coal rods class ; fluorite powder balls ; metallurgical slag ball class - dust, oxide, ore powder , raw ore, vanadium , nickel laterite ..... ; food industry category - fruits , vegetables, food processing , and so on . Especially in briquette production, for large briquette manufacturing enterprises , mesh belt dryer fully play its unique role.