calcined lime briquette machine summary

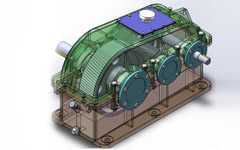

Previously, The lime powder are mostly abandoned in metallurgy industry in China, or for other purposes, causing a great waste of resources. With the resources increasingly tense energy, using the lime powder will be more and more attended for metallurgy industry. Since 2002 the Institute of metallurgical industry solved this problem through scientific research, namely using high pressure briquette machine,to make the kiln powder into briquettes, used for smelting, at present, some steel mills abroad and China's Baosteel mill, Anshan Iron and steel mill has been used this method to utilize lime powder. Zhongzhou high pressure briquette machine is a special briquette press quipment used for lime briquettes production.

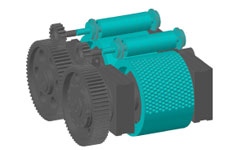

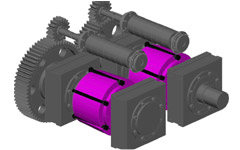

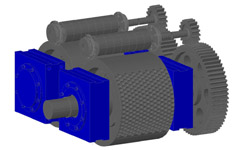

calcined lime briquette machine working process

The lime came from kiln is screened, the materials less than 3mm directly go into high pressure briquette machine, briquettes size is about 35mm*25mm*15mm (length * width * thickness), the shape and size also can also be designed in accordance with customer's requirements, get 1.9-2.2g/cm3 bulk density briquettes,falling strength is almost same with limestone. The qualified briquettes will go into the finished product bin for smelting after selection.

The characteristic of calcined lime briquette machine

Good effective pressure, high briquette rate, high strength; long service life for rollers; the double shaft reducer structure, improve the precision of rollers, the involute gear reducer, improve performance and life; the prepress device use speed motor, all wear resistant parts are alloy, improve the performance and service life; the hydraulic station is placed independently with overpressure protection function.

Purchase guidance:

Please inform the production requirements, the size of briquettes into its shape, the parameter table is based on the capacity of our company's standard briquettes size, calculated as the density of lime into the briquettes.

Zhengzhou Zhongzhou Briquette Machinery Plant has formed a research and development, design, manufacture, test and service of professional equipment manufacturers in China briquette machine industry, and equipped with the perfect test room of briquette machine , our factory can determine the process process and process parameters, and complete the model selection and design and manufacture based on users' material through experiment, that is the most complete and specific briquette machine manufacturing base. Welcome to visit our factory!