Silicomanganese briquette is composed of manganese, silicon, iron and a small amount of carbon and other elements of alloy, it is a widely usage. Silicomanganese briquette is a common compound deoxidizing agent in steelmaking, but also the deoxidizer of manganese metal in production of low carbon ferromanganese and electrosilicothermal method. Silicomanganese briquette can take continuous operation in large, medium and small smelting furnace for smelting, using silicon manganese briquettes can reduce the cost than the use of silicon manganese alloy block.

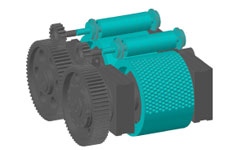

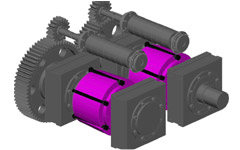

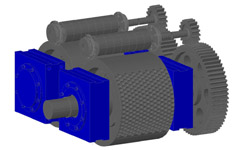

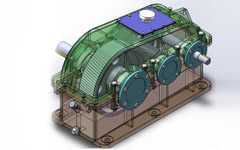

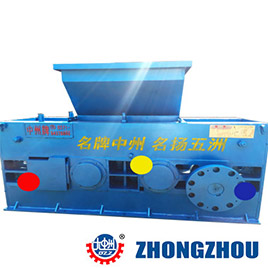

Zhongzhou hydraulic silicomanganese briquette machine is designed for silicomanganese,ferrosilicon,iron powder, iron oxide, oxide coating, iron scale, iron ore concentrates,iron mud to make briquettes, high pressure, stable operation, high productivity, high degree of automation, production efficiency, low failure rate, convenient maintenance, so Zhongzhou Silicomanganese briquette machine are welcomed by many domestic and foreign enterprises.

The requirements for raw materials of silicomanganese briquettes production:

1, the particle size of the raw material should be between 0-5mm.

2, can not contain impurities, especially large metal. Such as nails, or iron, rocks, it very likely damage roller and spindle..

3, the feeding of whole produciton line should be stable, even, ensure workloads of briquette machine stable, to get high efficiency of production.

Zhongzhou company based on metallurgical briquette press equipment technical services, to create maximum value for clients, silicomanganese briquette machine we produced has the high pressure, high finished product rate, high strength, fully meet the requirements of the operation of steelmaking, cost reduction for the production of smelting, optimized operation,shorten smelting practice term, speed up the rhythm of steel making, create the conditions for the realization of maximum benefit, we sincerely welcome all steel enterprises to explore, mutual benefit and win-win.