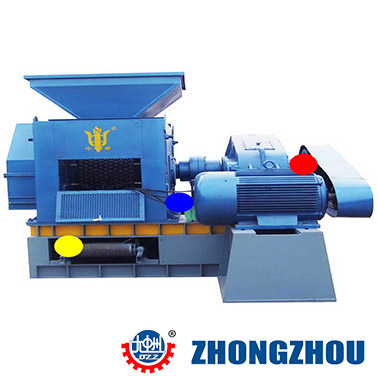

Fluorite is mainly used in the metallurgical industry of iron, steelmaking and iron alloy as flux, slag agent. Due to the properties of materials, are not allowed to add any water in briquetting process, so the user needs to select the high pressure briquette machine, instead of the ordinary pressure briquette machine to complete briquetting, Zhongzhou high pressure briquette machine is a special equipment for pressing fluorite.

The characteristic of fluorite briquette machine

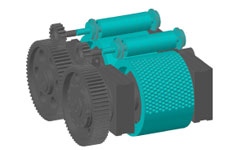

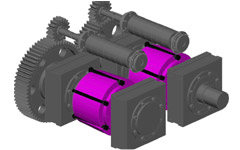

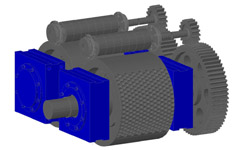

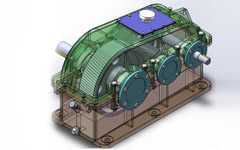

Good effective pressure, high briquette rate, high strength; long service life for rollers; the double shaft reducer structure, improve the precision of rollers, the involute gear reducer, improve performance and life; the prepress device use speed motor, all wear resistant parts are alloy, improve the performance and service life; the hydraulic station is placed independently with overpressure protection function.

Fluorite briquetting means can replace high grade fluorite ore, has the advantages of uniform size,The grade can be controlled easily, is widely used in various industries: 1. Metallurgy Industry: mainly as the flux, slag agent of iron, steel and iron alloy, fluorite briquettes can lower the melting point of refractory material, promote the slag flow, make the slag and metal separate well, desulfurization, dephosphorization in the smelting process, reinforced metal can be calcined and tensile strength, the general amount of mass fraction is 3% ~ 10%. 2, the cement industry: in the production of cement, fluorite as a mineralized agent . Fluorite can reduce the sintering temperature of the burden, reduce fuel consumption, but also enhance the viscosity of liquid phase sintering clinker, promote the formation of three calcium silicate.

Purchase guidance:

Please inform the production requirements, the size of briquettes into its shape, the parameter table is based on the capacity of our company's standard briquettes size, calculated as the density of lime into the briquettes.

Zhengzhou Zhongzhou Briquette Machinery Plant has formed a research and development, design, manufacture, test and service of professional equipment manufacturers in China briquette machine industry, and equipped with the perfect test room of briquette machine , our factory can determine the process process and process parameters, and complete the model selection and design and manufacture based on users' material through experiment, that is the most complete and specific briquette machine manufacturing base. Welcome to visit our factory!