In order to recycling semicoke resources, solve the problem of shortage of waste coke, solve the environmental pollution; make full use of various types of coal, coke,semicoke, "clean coal" instead of "original coal", more and more large market demand. Zhongzhou semicoke briquette machine will work in the production of clean coal briquettes, which plays an important role that pressing semicoke briquettes, high pressure, stable operation, high productivity, high degree of automation, production efficiency, low failure rate, convenient maintenance makeZhongzhou semicoke briquette machine more and more popular at home and abroad.

The semicoke briquettes production process:

A complete semicoke briquettes production plant includes crusher, feeder, mixer, dryer, coal briquetting machine and conveyor. The final semicoke briquettes can be used as fuel in cement industry and other industries using boilers for steam generation. First of all, let's have a look at the flowchart of entire briquetting line.

1. Rotary Dryer

Rotary dryer can be widely used to dry materials with humidity or granularity in the industries of mineral dressing, building material, metallurgy and chemical, such as metallic and nonmetallic mineral, clay in cement industry and coal in coal mine, etc. Wide supply scope and simple operation are the main features of it.

2. Compound Crusher:

Compound Crusher is designed and optimized in accordance with international latest crushing technology. It can crush all kinds of hard ores in mining, metallurgy, refractory, cement , coal, glass, ceramics, and electric power industries.Widely used in stone crushing line and sand production line, Compound Crusher is suitable for limestone, clinker, coal and other minerals of building materials, mining, metallurgy, chemical industry. Its compressive strength is not more than 140 Mpa and humidity less than 15%.

3. Feeder:

This machine is an automatic proportioning feeder which is used together with a mixer. It can automatically perform feed proportioning procedure according to the proportion setup pf customers. Besides, it can fit with one or two sets of mixers, thus improving the working efficiency. The machine is composed of feeding unit, proportioning unit, electronic control system, etc.

4. Double-shaft Mixer:

Double shaft mixer is used for mixing materials continuously and uniformly. During mixing, the raw material can be uniformly mixed with binder, and after mixed, the blended materials can be continuously sent to the conveyor. It is usually applied to mix coal, mineral powder, iron powder, coal slurry, sludge, clay, etc. Double shaft mixer has the features of high mixing speed and good uniformity.

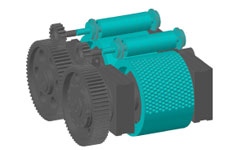

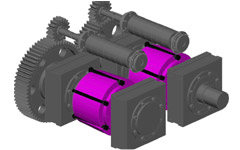

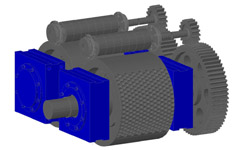

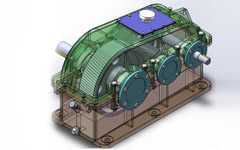

5. Semicoke Briquette Machine:

Semicoke briquette machine is mainly used for pressing materials with low water content such as coal and semicoke. Zhongzhou semicoke briquette machine is a new type of briquette machine with high efficiency, energy conservancy and environmental protection. The final briquette is in 20-80mm, its shape shall be round, pillowed, squared, oval like egg etc, energy saving,environmental friendly, and easy to transport, which make it have good economic and social benefit.

6. Mesh Belt Dryer:

The Mesh belt dryer is a kind of batch, continuous production drying equipment, mainly for better ventilation sheet, strip and granular materials, such as: preserved fruit, pepper, potato chips, cassava chips/slice, briquettes, grain straw, etc. The main types of heating include electric heating, steam heating and hot air heating.

8. Belt Conveyor:

Belt Conveyor is a kind of machine to transfer the material continuously. Its transfer capacity is high, transfer distance is long. It can work under the temperature situation ranging from -20℃ to +40℃. The temperature of transferred material by this belt conveyor should be lower than 50℃.

The coal (coke) briquettes production process is with the advantage of automatic control, continuous production, is the world's leading level, the world competing countries in the development and promotion of new technology. This project not only solves the utilization rate of semicoke is low, and can improve atmospheric environment and energy conservation.

The requirements for raw materials of semicoke briquettes production:

1, the particle size of the raw material should be between 0-5mm.

2, can not contain impurities, especially large metal. Such as nails, or iron, rocks, it very likely damage roller and spindle..

3, the feeding of whole produciton line should be stable, even, ensure workloads of briquette machine stable, to get high efficiency of production.

Making clean coal briquettes by ZHONGZHOU clean cal briquette machine(civilian):

1. The main raw materials: bituminous coal, anthracite coal, semi-coke.

2. Accessories: a variety of organic additives (binder, modifier etc.).

3. Features: more inflammable than anthracite, clean and smokeless, high calorific value (5300~6000 calories), environmental protection.

4. Product performance characteristics: good reliability, production can be controlled well.

5. Price: cheap (900~950 RMB / Ton), as the main raw material is a by-product of semi-coke which is from at the end of the dry distillation of bituminous coal, the price is cheap.

6. packaging: 25 kg standard woven bag packaging.

7. Logistics: it is easy to close packed transportation to solve the dust pollution in the process of logistics.

8. Promotion: since the clean coal briquettes is from sufficient raw materials, cheap, clean, environmentally friendly products, reliable performance,production controlled, it will the ideal product that replaced powder coal burning in near the future.

Making squared coal briquettes (civil central heating, industrial use)

1. Main raw materials: all kinds of low quality coal, raw material sufficient.

2. Accessories: a variety of additives (such as: sulfur fixing agent, binder, modifier, etc.).

3. Squared coal briquette features: clean, smoke-free, environmental protection, low calorific value (usually less than 4000 calories), product performance characteristics: production reliability.

4. Price: super cheap (450~500 RMB / Ton), highly competitive.

5. Packaging: carton packaging.

6. Logistics: easy to close packed transportation.

7. Shortcomings: the need for special stove, the stove only can heating, not cooking.

8. Promotion: it is the most ideal briquettes as heating, cheap price, easy production and environmental protection, production controlled, adequate raw materials.

Semicoke briquettes has six advantages:

1. It is easy to burning,has high calorific value, is two times than the calorific value of traditional bulk coal, greatly reducing coal consumption.

2. It production safety, it has no black smoke, no odor, very low harm to the human body.

3. It is more convenient.

4. It is more environmental friendly, clean coal briquettes has no dust when burning, less harmful, low sulfur content, not cause air pollution;

5. It is more energy saving, the comprehensive energy efficiency is more than 50% in the combustion;

6. It is more economical.