Introduction of carbon powder ash ball production line

In modern industrial production, in order to pay attention to the balance between industrial development and environment, improve resource utilization, reduce pollution has become the mainstream. Carbon powder ball production line is more automated, higher production capacity, can be continuous production of powder material ball production line. From the crushing of raw materials to the end of the completion of the ball egg drying. Reduce the work intensity, improve production efficiency. A wide range of materials. For the development of economy and the harmony of resources and environment, but also to bring greater benefits for enterprises.

Characteristics and advantages of carbon powder ball production line

1, carbon powder ball production line automation level, reduce the labor intensity of workers.

2, from the selection of raw materials to the final forming one-stop, more efficient.

3, large capacity, continuous production can be achieved uninterrupted.

4, toner ball production line can be reliable, stable, equipment maintenance and maintenance is simple and convenient.

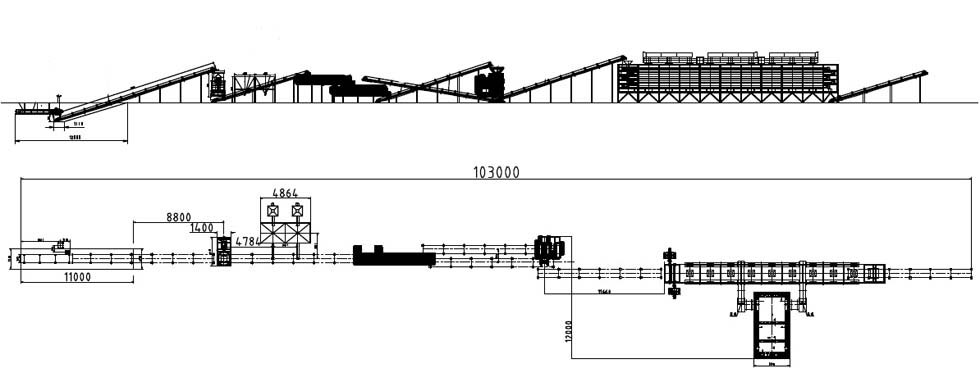

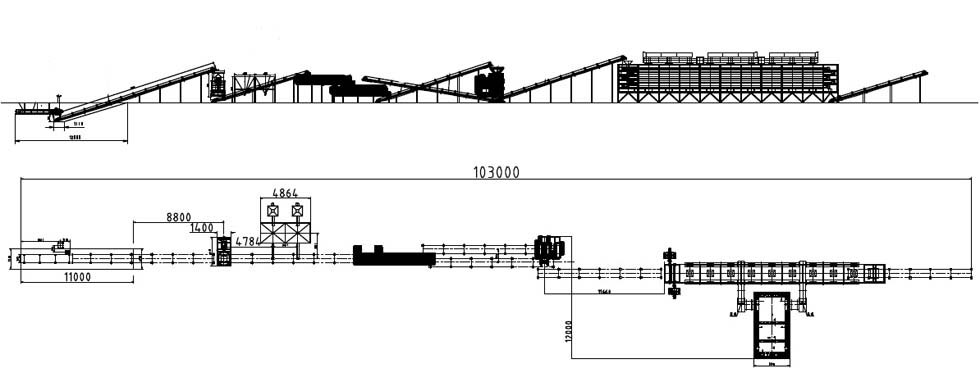

Flow chart of carbon powder ash ball production line:

Main equipment of carbon powder ball production line:

1, the box type quantitative feeder, the raw material quantitative uniform delivery to vertical grinder.

2, vertical mill, crushing the raw materials to the appropriate size, generally in the following 5mm is most suitable for finished products.

3, mixing barrels, used for liquefied adhesives (if the use of dry ball, need other equipment).

4, double shaft horizontal mixer, raw materials, adhesives, water to be fully mixed, the adhesive evenly distributed in the raw materials, in order to achieve better thermal strength, better ball system.

5, toner pressure ball machine, the core equipment in the production line, the pre mixing materials are pressed into the ball, spherical and size can be customized, Zhengzhou Zhongding machine can provide a variety of shapes and sizes and leather making.

6, vertical drying machine, to suppress the wet ball drying treatment, direct transportation, storage or bagging treatment.

7, belt conveyor, connected to the equipment, the whole coal ball production line automatic protection.

Spot of carbon powder ball production line

Material handling requirements

1, carbon powder ball production line material size should be within the standard range.

2, the purity of materials must be guaranteed, especially hard metal containing large particles. Such as nails, it is likely to damage the roller surface.

3, in order to maintain high efficiency production of carbon powder ball production line, aluminum powder ash ball production line supply should be uniform and stable.

Production process of carbon ball production line are as follows (this figure only as a flow chart, the specific size, site planning and layout for different users, this is not. If necessary, please call +8618539955836. Free of charge based on your actual site Zhengzhou tripod machine provides annual production capacity of 1-30 tons of carbon powder ball production line of free configuration, site planning, field projects, welcome your advice!